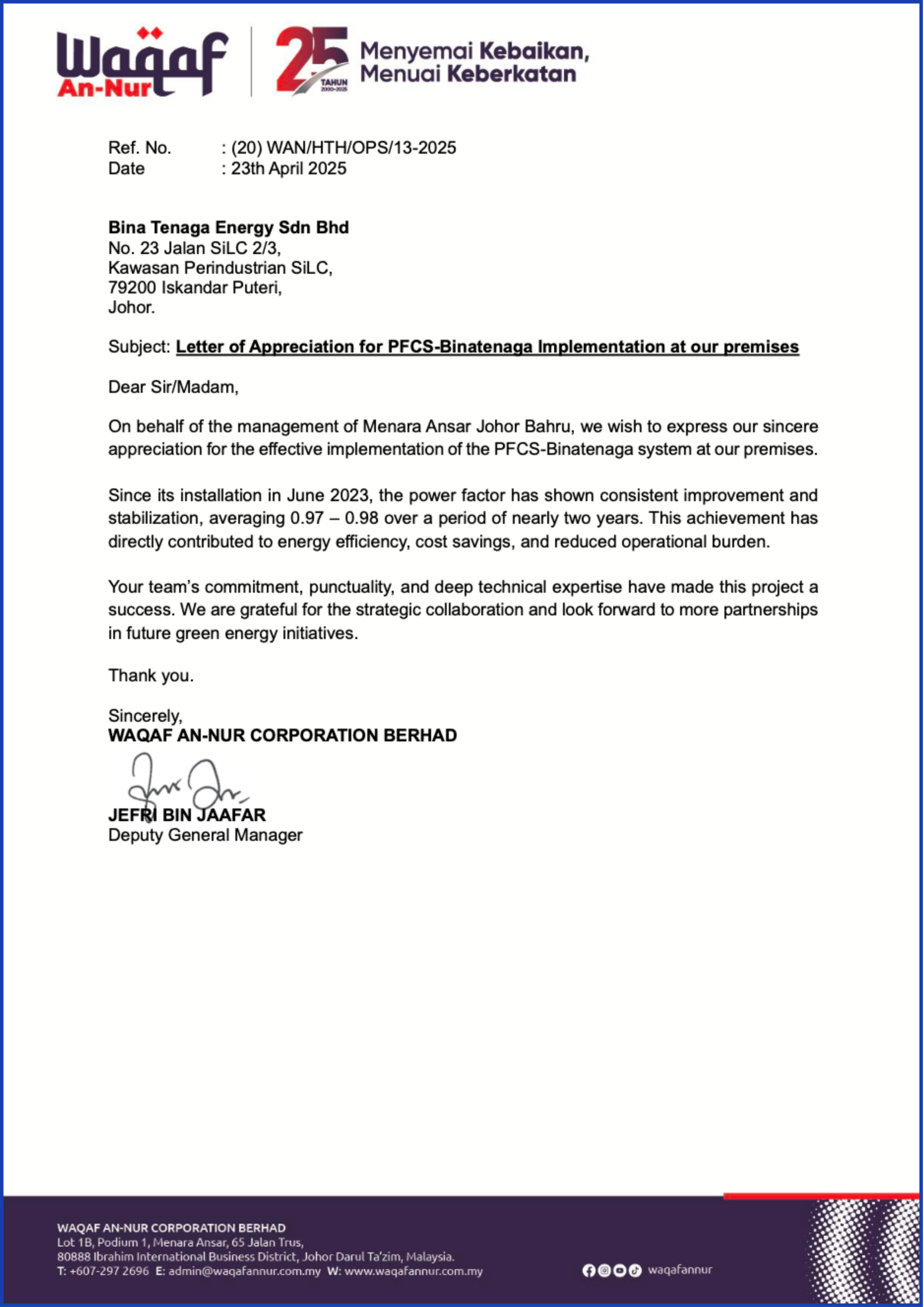

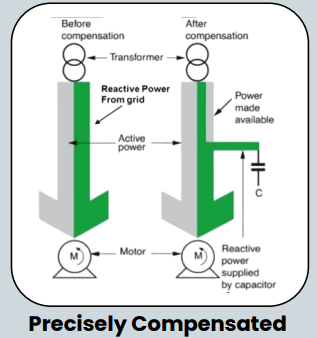

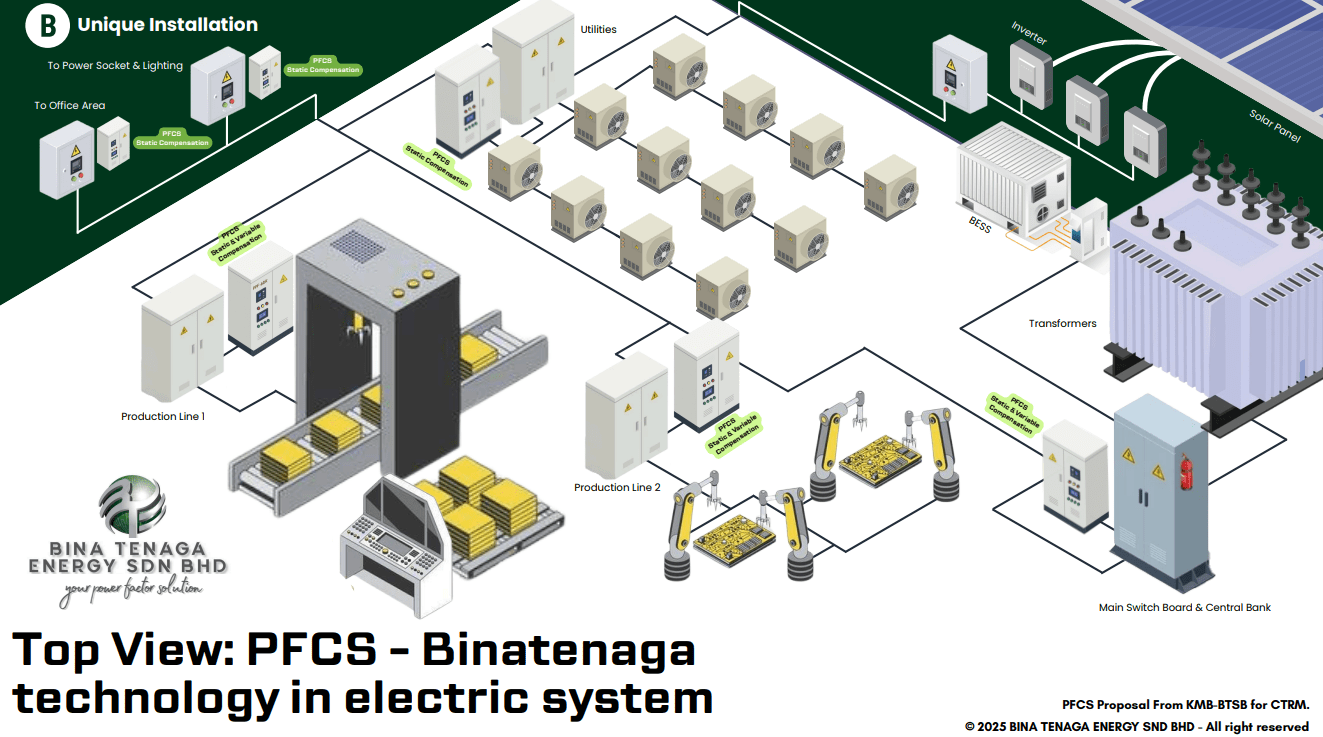

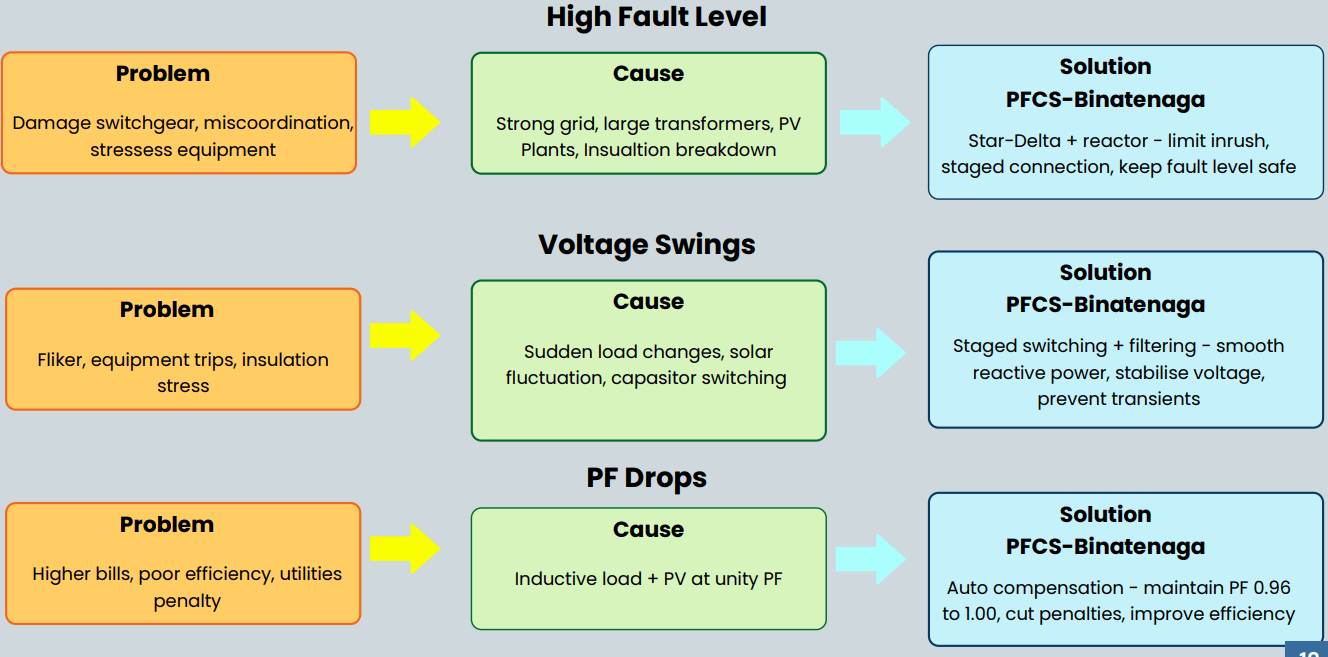

Bina Tenaga Energy Sdn Bhd — capacitor-based energy solutions with strong R&D

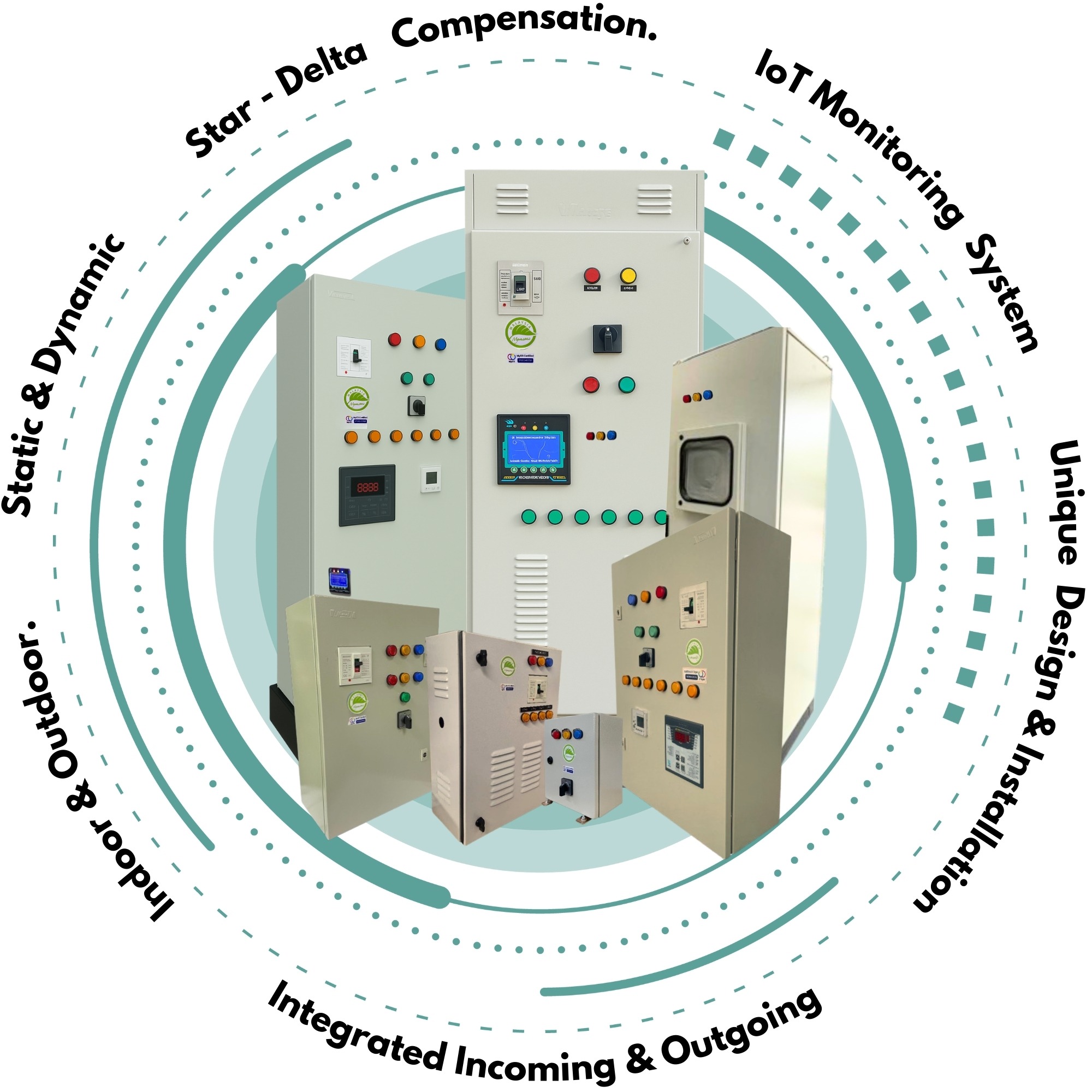

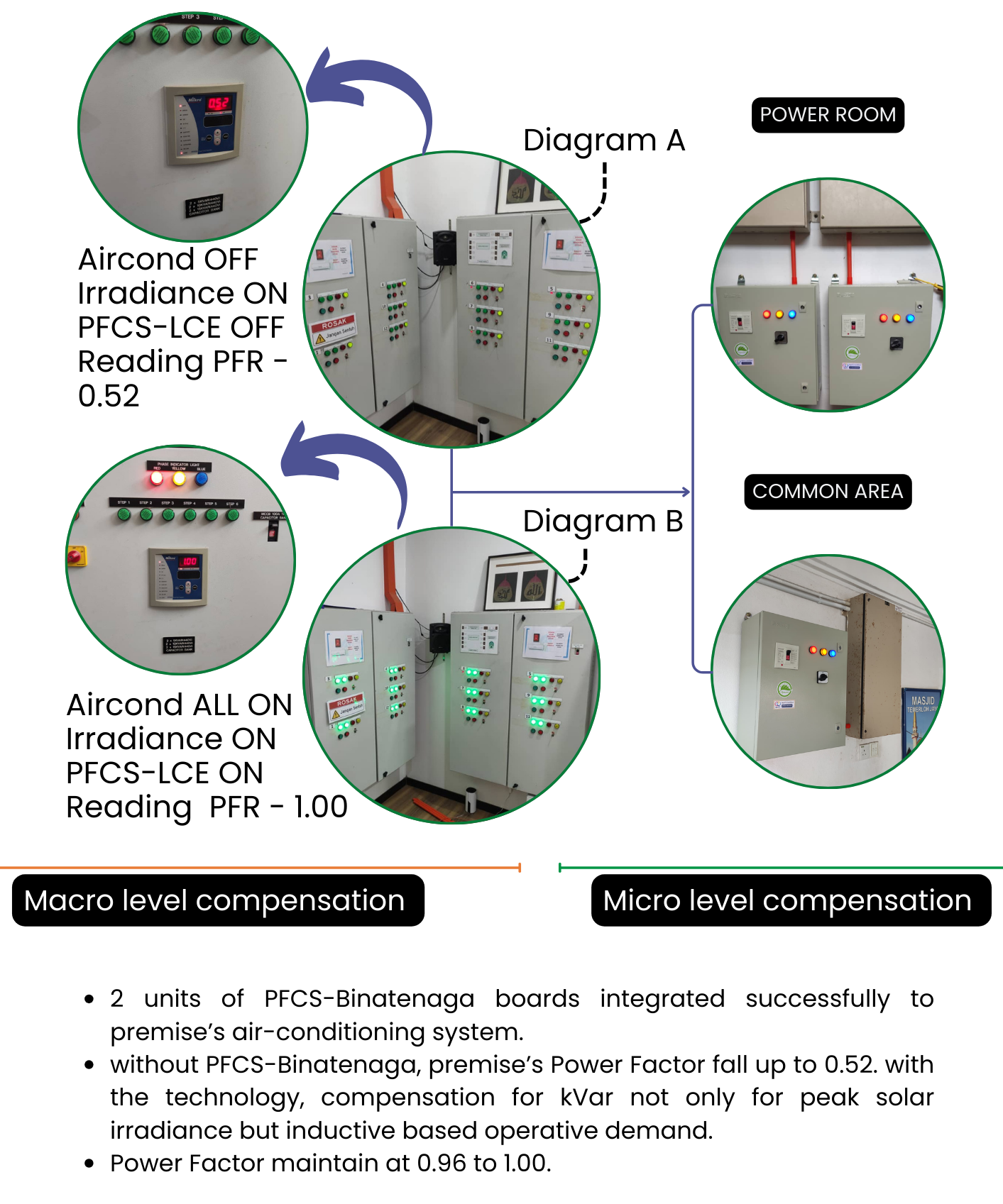

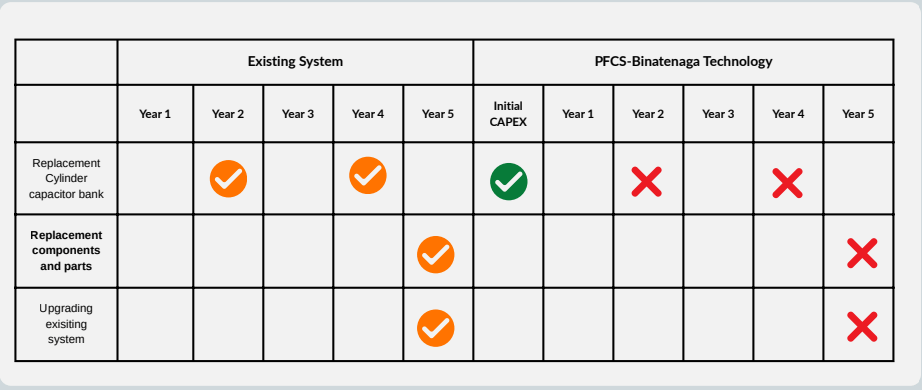

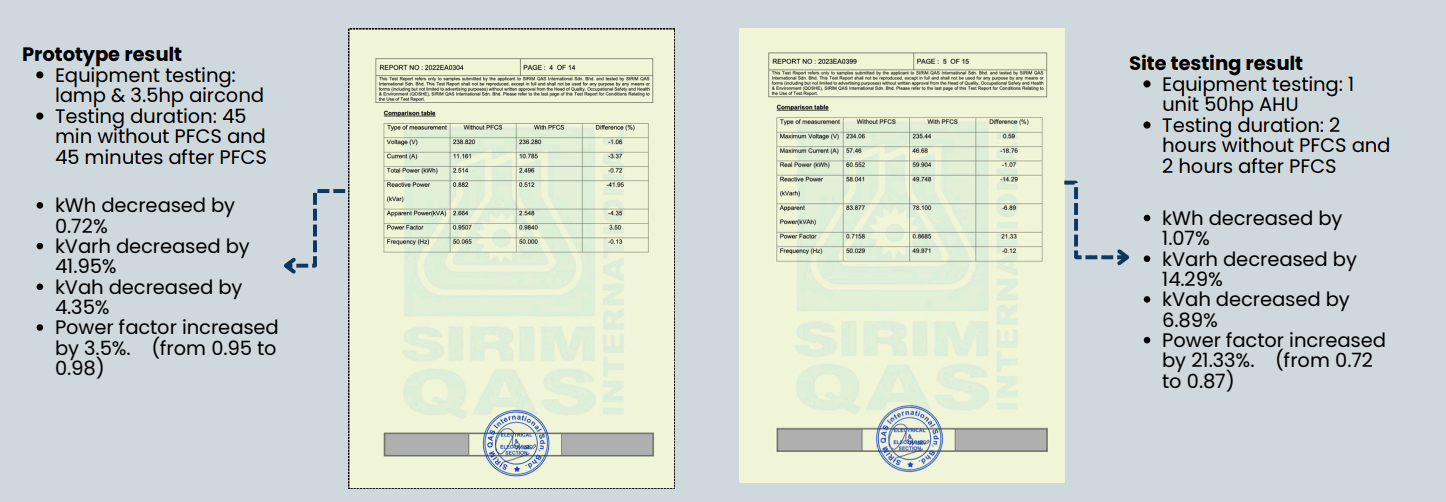

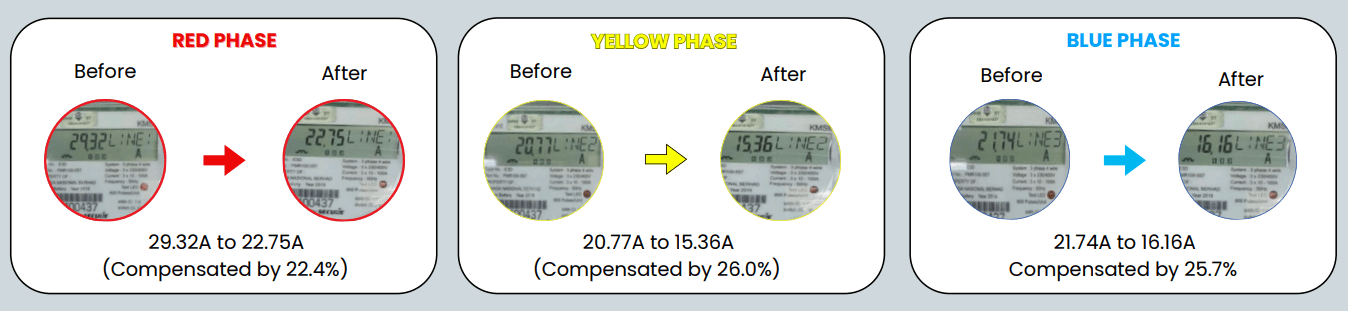

BTESB is a Malaysian company specializing in assembly, electrical wiring, installations, and technical services. Founded in 2006 and incorporated in 2021, we continue to grow in capability and innovation to deliver reliable, efficient energy solutions.